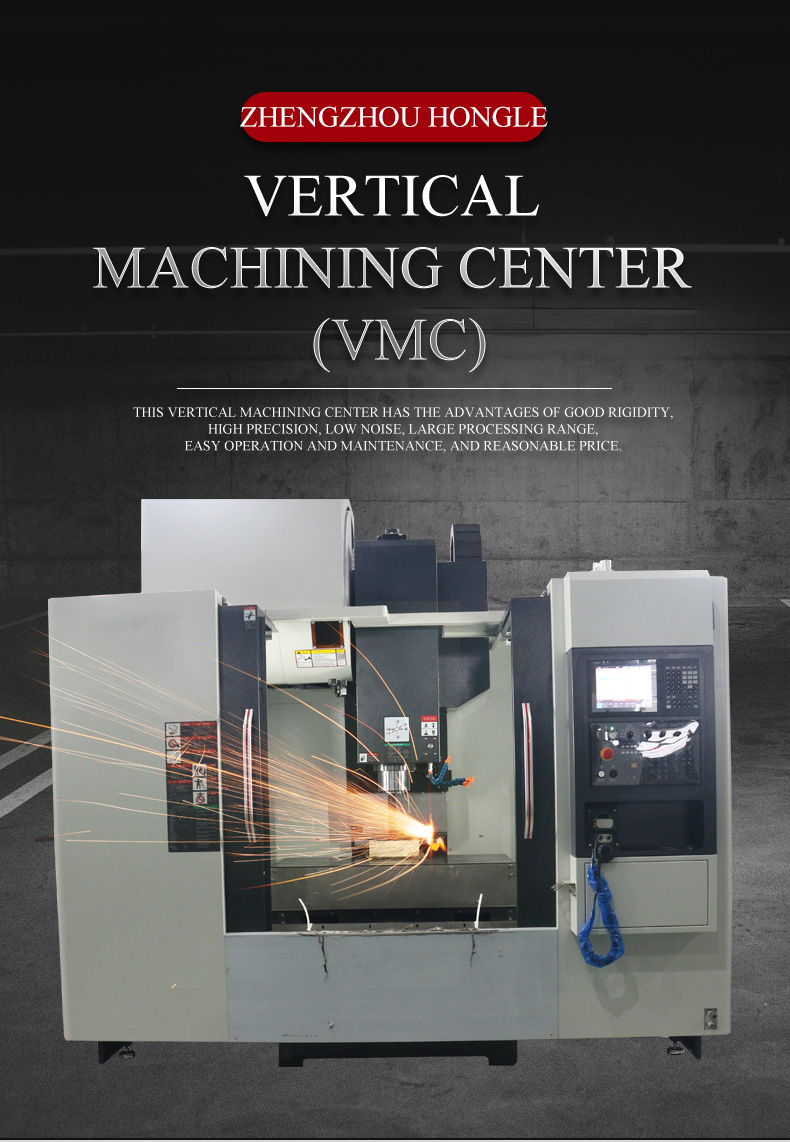

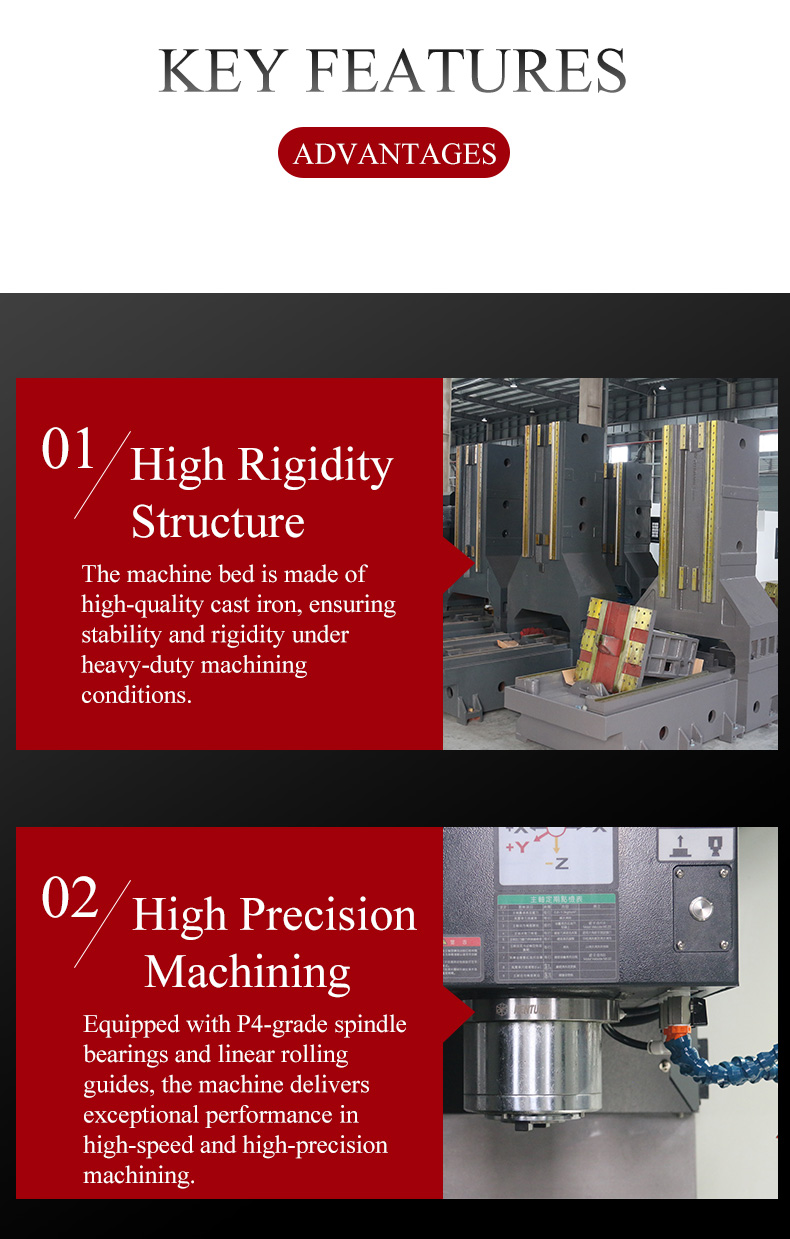

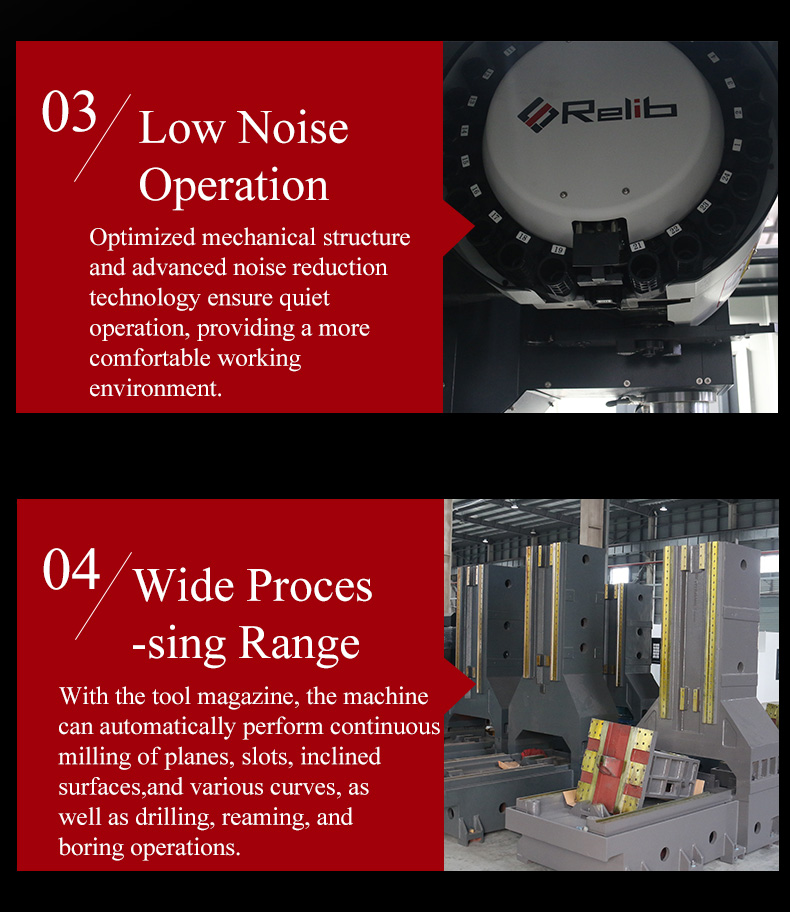

Our vertical machining center is a high-quality, high-precision, and high-performance technology-intensive product, designed and manufactured with advanced engineering techniques. It offers excellent rigidity, high accuracy, low noise, a wide processing range, easy operation and maintenance, and competitive pricing. This machine is versatile and, when equipped with a tool magazine, can automatically perform continuous milling of planes, slots, inclined surfaces, and various curves, as well as drilling, reaming, and boring operations.

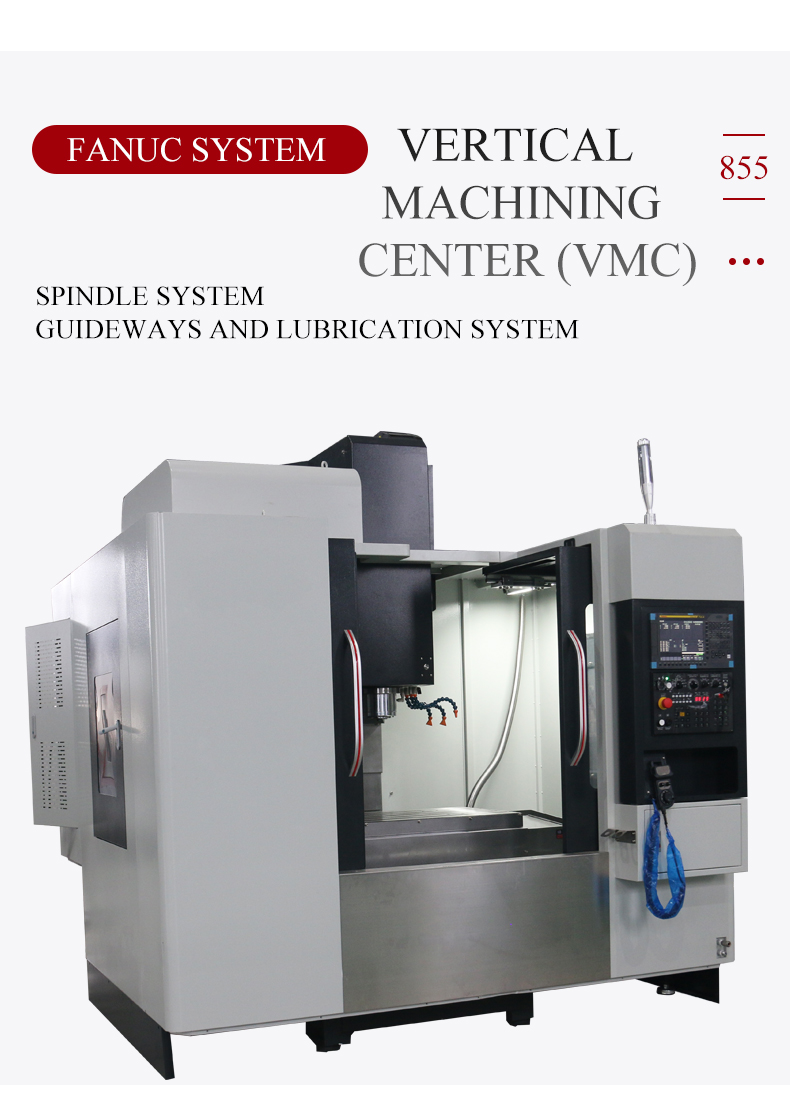

Spindle System

1.Imported Spindle System: The complete spindle system is imported from professional manufacturers in Taiwan, ensuring high reliability and long service life.

2.Reinforced Components: Key components are reinforced to ensure stability under long-term heavy-duty operation.

3.Precision Assembly: The entire spindle is assembled in a constant temperature environment, balanced by computer, and run-in tested to ensure high precision and low vibration.

Guideways and Lubrication System

1.Linear Rolling Guides: The machine is equipped with linear rolling guides on all three axes, enabling high-speed and high-precision positioning.

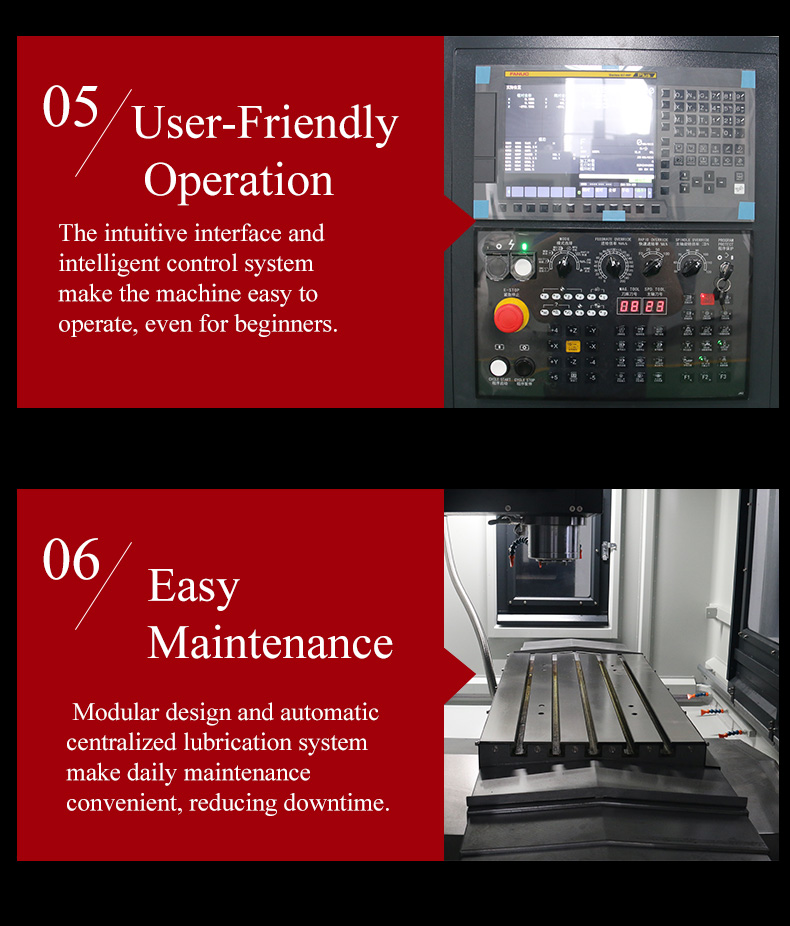

2.Automatic Centralized Lubrication System: Ensures all lubrication points are adequately lubricated, reducing wear and extending the machine's lifespan.

| Model | HL-VS-855 |

| Workbench area | 1000*550MM |

| Spindle taper | BT40 |

| Maximum weight of tool with full blade | 192kg |

| Machine size | 2700*2400*2800mm |

-

nodata

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.