-

The Heat Pump Dryer is an energy-efficient drying equipment that utilizes air source heat pump technology to extract heat from the environment, converting it into high-temperature air for moisture removal. With a closed-loop system, it reduces energy consumption by 50% compared to traditional electric dryers, making it ideal for industrial and commercial dehydration needs. Equipped with adjustable temperature (20-80℃) and humidity control, it ensures gentle, uniform drying—preserving the color, flavor, and nutrients of materials. Constructed with stainless steel, it meets food-grade standards and is widely used in food processing, agriculture, and industrial fields.

Heavy-Duty Heat Pump Tumble Dryer | Dry Fruit Machine, Commercial Dehydrator for Meat

-

The advanced apple juice production line uses a belt press as the juicer; the filtration equipment uses ultra-fine filtration technology to replace traditional clarifiers, mechanical separation and filtration unit operations; the concentration device uses a triple-effect falling film evaporator and flash evaporation new technology, with large output and high concentration efficiency.

The advanced apple juice production line uses a belt press as the juicer; the filtration equipment uses ultra-fine filtration technology to replace traditional clarifiers, mechanical separation and filtration unit operations; the concentration device uses a triple-effect falling film evaporator and flash evaporation new technology, with large output and high concentration efficiency.

Apple juice concentrate production line

-

A stone mill is an ancient yet timeless milling device that utilizes a pair of circular millstones to process whole grains, nuts, and seeds into flour or pastes through a crushing and shearing action. Its fundamental principle has remained largely unchanged for millennia, prized for its ability to produce exceptionally high-quality, nutritious, and flavorful products. The core components of a stone mill are the millstones. Traditionally, these are carved from natural materials like granite or basalt, chosen for their hardness and natural, slightly porous texture. One stone is fixed (the bedstone), while the other rotates above it (the runner stone). The facing sides of both stones are engraved with a patterned series of grooves called furrows and flat areas called lands. These patterns are critical: they act as channels to draw raw grain into the center and distribute it evenly across the grinding surface, while the sharp edges of the lands perform the actual cutting and crushing. The process begins when whole grain is fed into the eye, a central hole in the runner stone. As the runner stone rotates—either by hand, water power, or in modern applications, an electric motor—the centrifugal force moves the grain outward between the stones....

Commercial Automatic Stone Grinding Mill CE Certified Traditional Stone Mill for Grain and Flour Production

-

Automatic Small Bottle Liquid Filling Capping and Labeling Machines Bottle Packing Filling Machine Production Line for Bottling

-

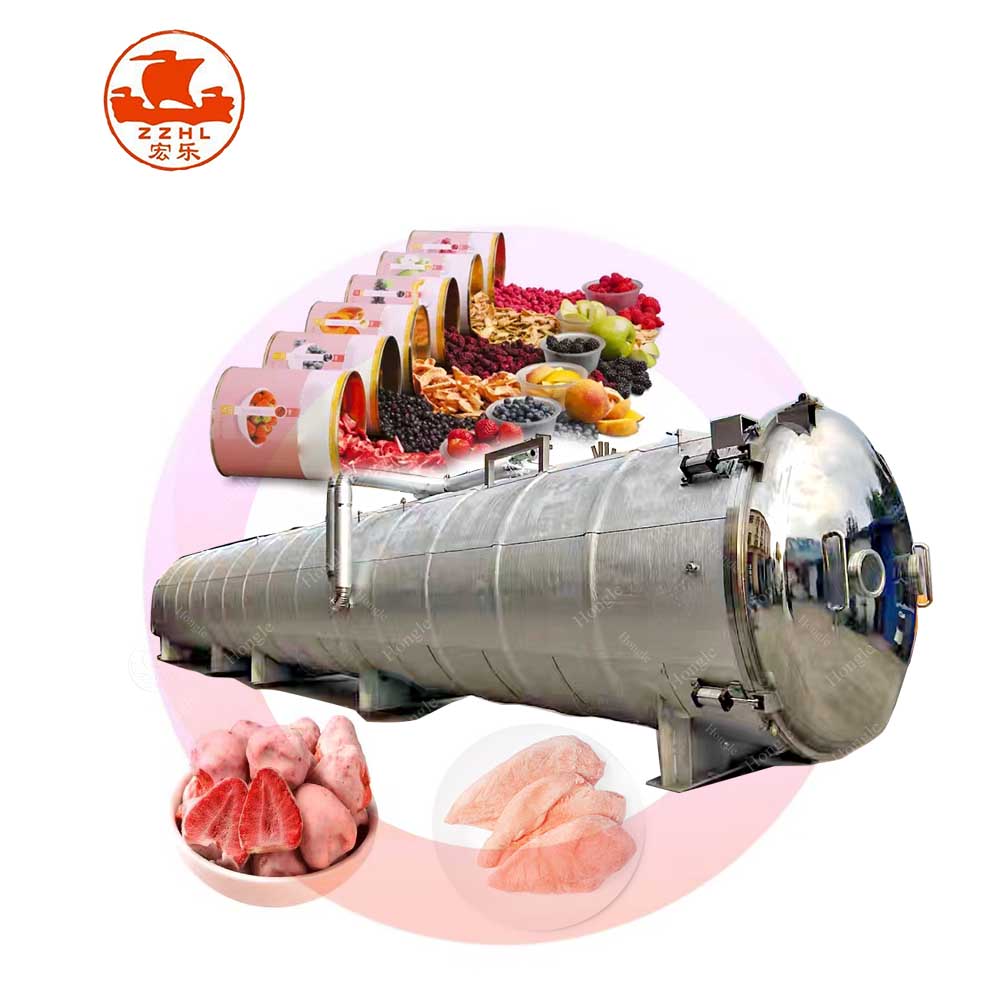

Vacuum Fruit Freeze Drying Machine Lyophilizer

-

Egg cracker production line, combining precise egg cracking, eggwhite and yolk separation and egg liquid collection functions inone, efficient and stable operation, greatly improving productionefficiency and guaranteeing the quality of egg liquid.

Industrial Commercial Liquid Egg White Yolk Separator Beating Break Extraction Machine Process Line