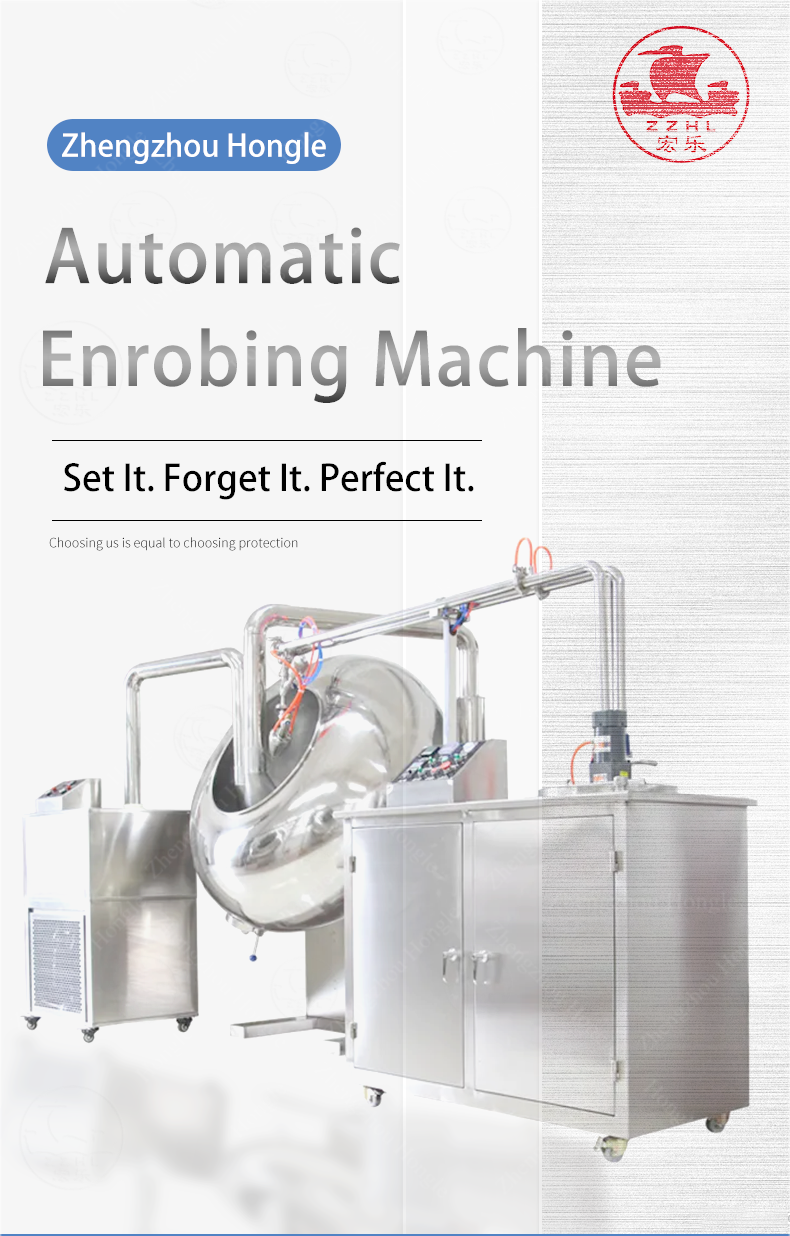

Commercial Food Coating Equipment: Coating Machine, Cooling Fan & Spray Cabinet

In the food processing industry, large-scale production often faces three core challenges: flavor inconsistency caused by uneven spraying, quality fluctuations due to insufficient coating precision, and production bottlenecks from delayed cooling. Now, the golden trio of “Coating Machine + Cooling Fan + Spray Cabinet” breaks down process barriers with a “Three-in-One” collaborative design, integrating the scattered processes of “spraying-coating-cooling” into a seamlessly connected high-efficiency production line. From uniform coating of chocolate beans to rapid freshness locking of baked cookies, and precise seasoning of snacks, this combination not only achieves a 99.5% coating integrity rate and ultra-fast cooling in 3-5 minutes but also increases overall production efficiency by 40% and reduces material loss by 25%. Fully complying with FDA food contact standards and industrial production needs, it serves as a core solution for controlling quality, cutting costs, and boosting capacity—whether for mass processing in large food factories or premium production in specialty workshops.

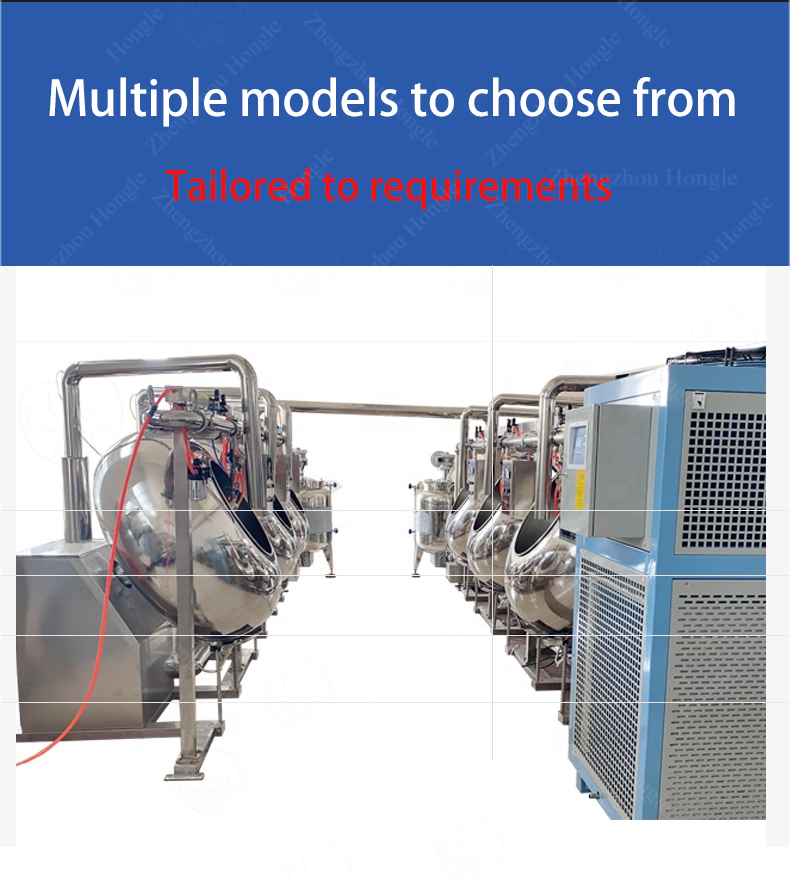

In the food processing industry, the "Three-in-One" combination of Coating Machine, Cooling Fan, and Spray Cabinet is the golden trio reshaping the full "spraying-coating-cooling" process. Centered on "synergistic value", this modular trio focuses on data-driven advantages and scenario-specific applications, delivering efficient solutions for food production through dual highlights of "single-machine performance + combined benefits".

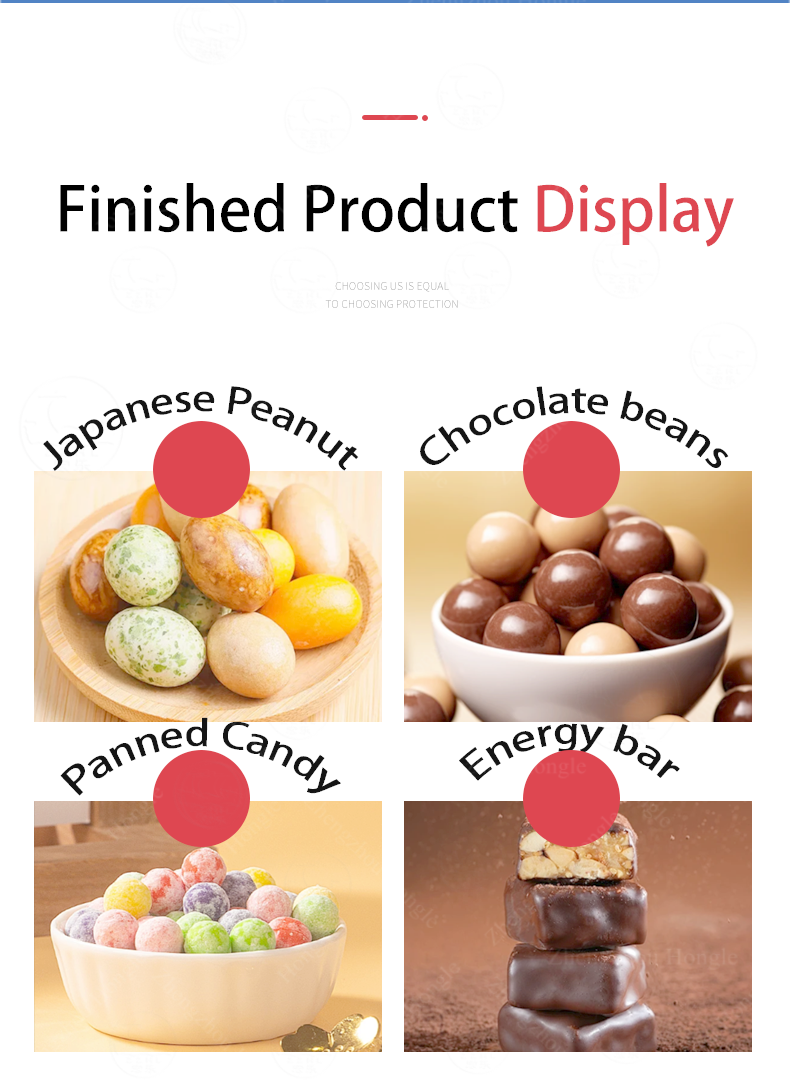

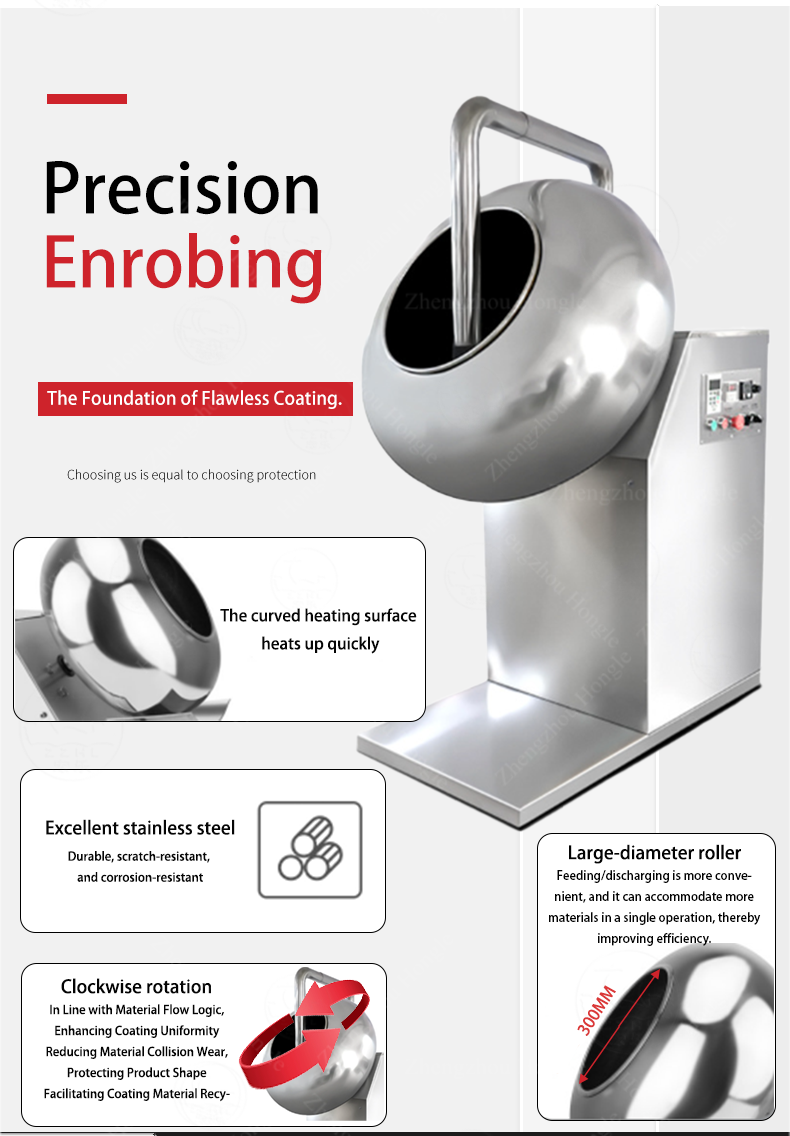

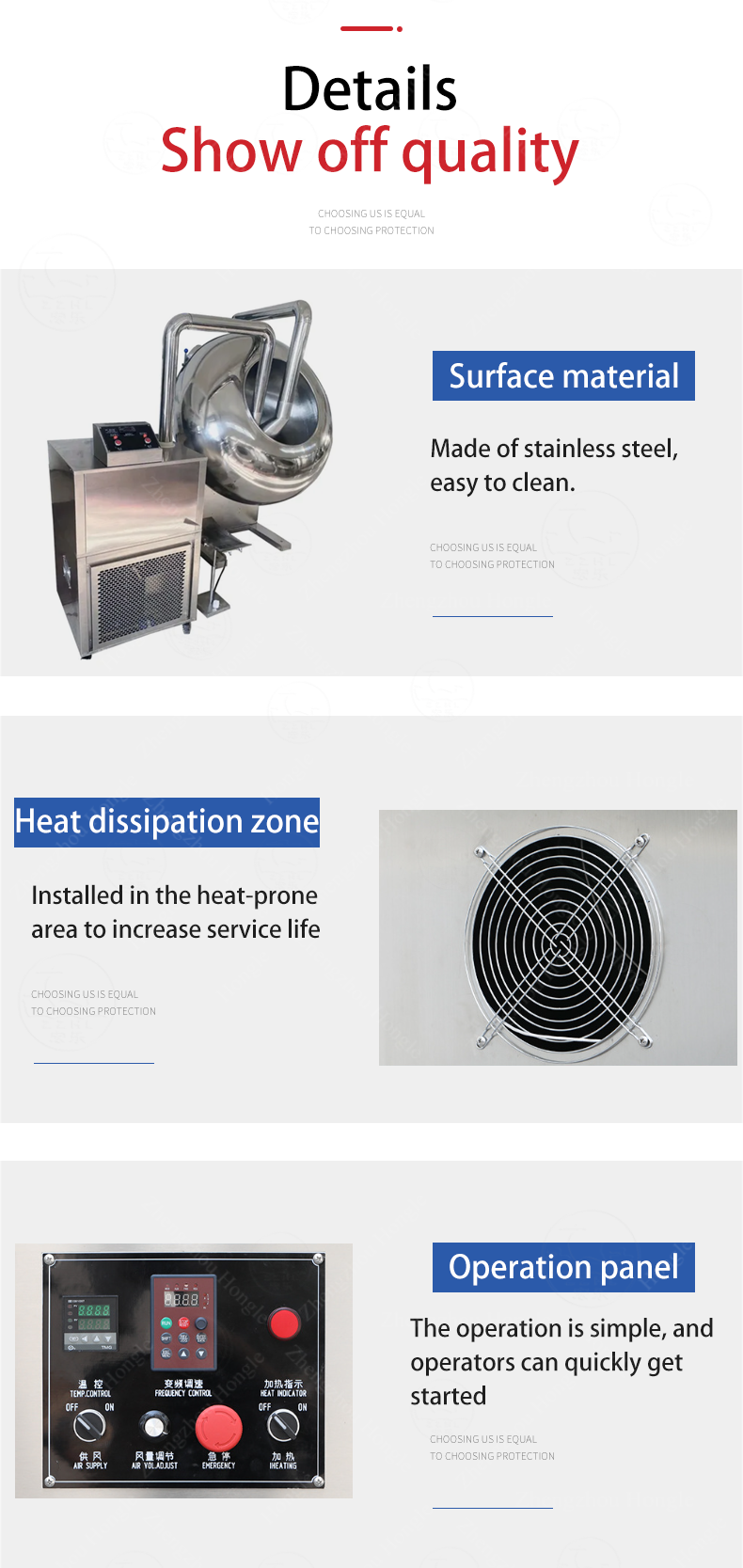

At the core of this trio, the Coating Machine acts as the "Quality Steward of Precise Coating". It controls coating thickness at 50-200μm (tolerance ≤±5μm) with over 99.5% coating integrity, while cutting coating material use by 15%-20% and energy consumption by 12%. Ideal for food, pharmaceutical, and health product factories (e.g., chocolate coating, tablet sugar coating), it lives up to its slogan: "Micron-precise, perfect coat for every product!"

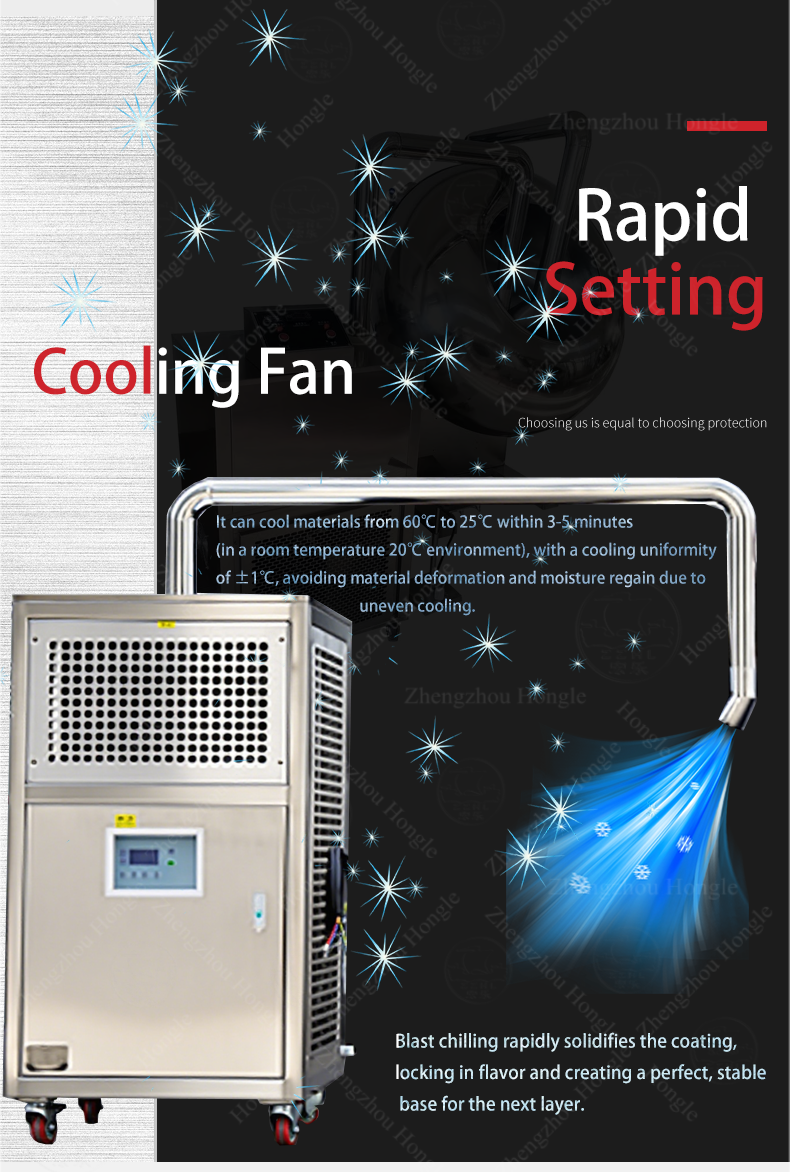

Complementing the Coating Machine, the Cooling Fan serves as the "Temp Control Expert for Rapid Freshness". It cools materials from 60℃ to 25℃ in 3-5 minutes (uniformity ±1℃), supports 0-10℃ adjustable temperature, reduces energy use by 20% vs. traditional models, and meets FDA food contact standards. Suitable for post-baking cookie cooling, chocolate coating setting, and candy anti-sticking, it embodies its slogan: "Ultra-fast freshness, every bite as fresh as baked!"

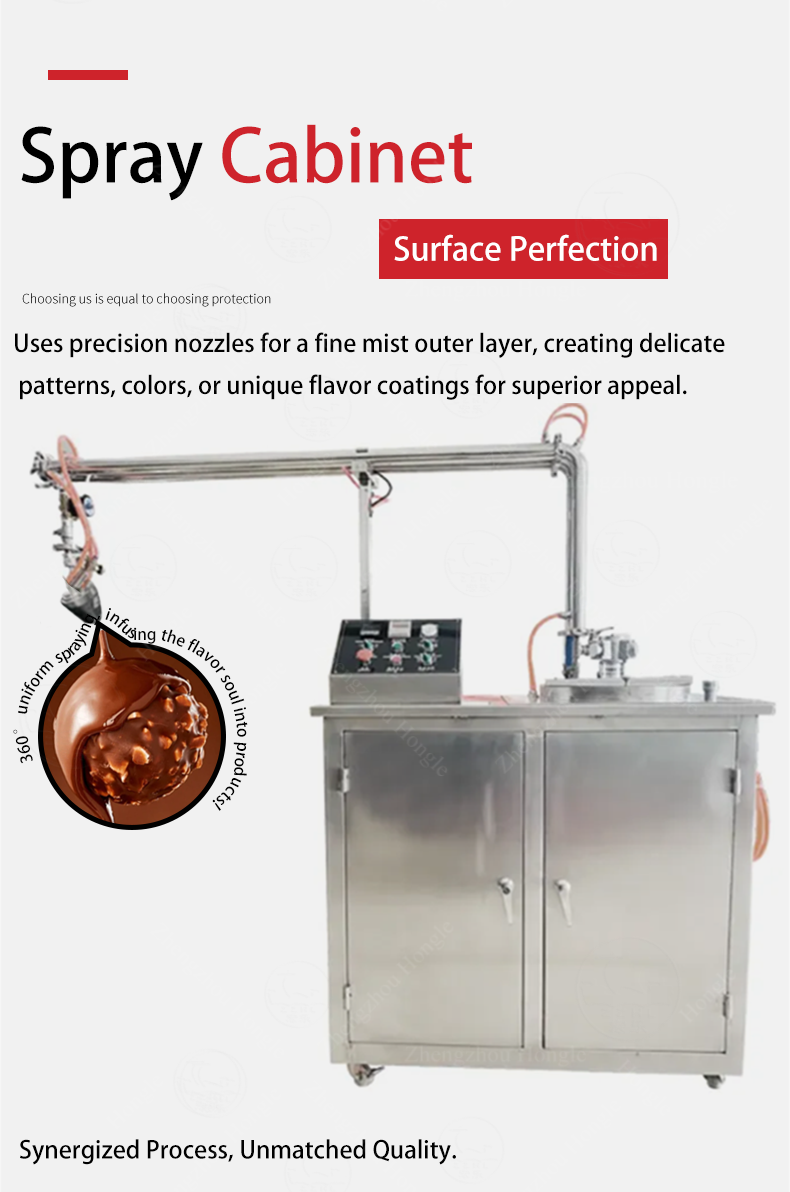

Rounding out the trio, the Spray Cabinet is the "Creative Engine for Uniform Spraying". Its 360° dead-angle-free design achieves ≥98% spraying uniformity, with adjustable flow (0.5-5L/min, tolerance ≤±0.1L/min) and 15-minute auto-cleaning to cut labor costs. It excels at snack sauce spraying (e.g., chip seasoning), baked goods frosting, and candy decoration, matching its slogan: "360° uniform spray, infusing flavor soul!"

When linked, the trio’s combined strengths shine: it forms a complete "spraying-coating-cooling" process, boosting efficiency by 40% and reducing material loss by 25% vs. separate operation. Perfect for large-scale production in food factories, it proves its core value as its slogan says: "One trio replaces three, full process, doubled efficiency!"—a reliable tool for food processors to enhance quality and cut costs.

Related Products

-

nodata

Inquiry

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.