-

This 800 Mesh Ultra-Fine Grinder is a specialized machine designed for producing ultra-fine powders with a fixed fineness of 800 mesh, paired with adjustable output capacity (10-200kg/h). It integrates high-speed impact grinding and precision air classification technology to ensure 98% of particles meet the 800-mesh standard—perfect for materials requiring exquisite texture, such as herbs, spices, and food additives. Constructed with 304 stainless steel contact parts and equipped with PLC automation, the machine complies with food-grade standards and CE certification, making it a reliable choice for small to medium-scale food processing plants, herbal workshops, and spice manufacturers.

150-400 Mesh Ultra-Fine Grinding Machine | 304 Stainless Steel, CE Certified

-

Cashew Shelling Production Line

-

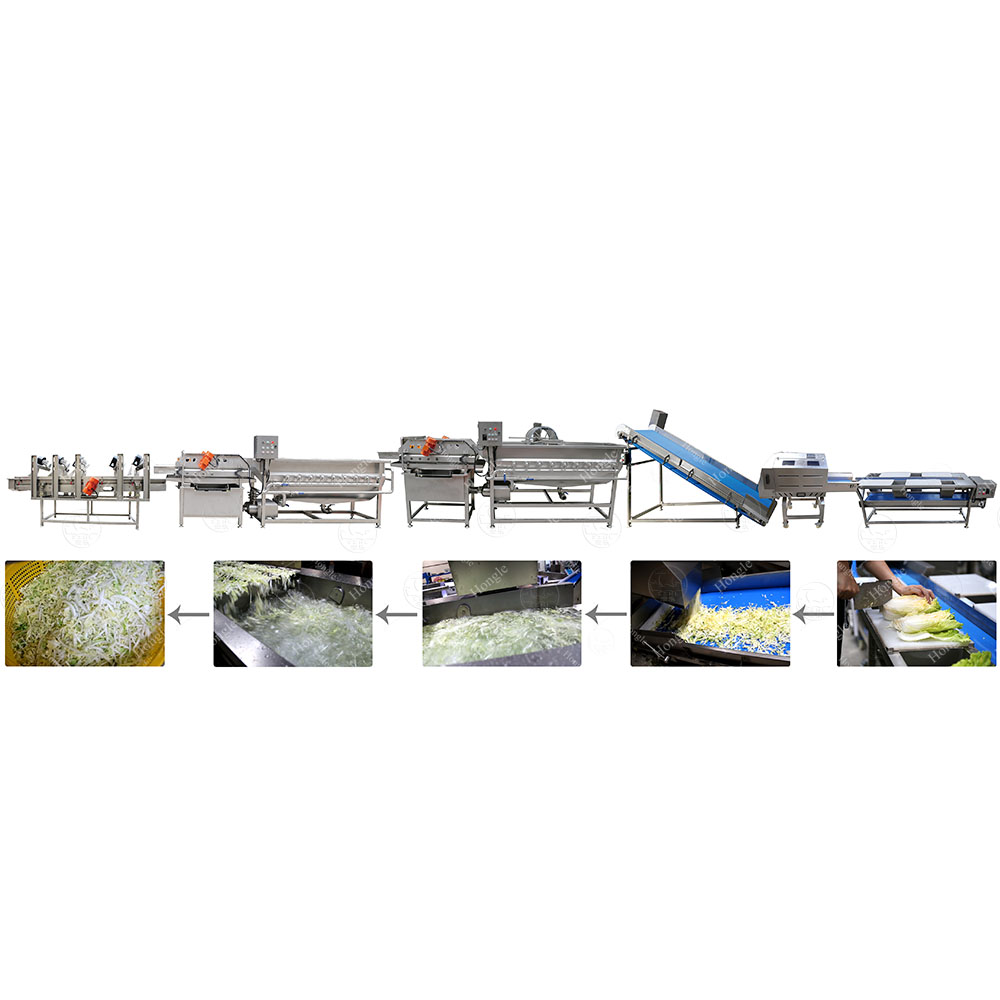

Cleaning And Cuttings Wash And Drain Vegetables Leaf Machine Line

-

Automatic Horizontal Round Bottle Labeller Labeling Machine From China

-

With electricity (microwave) heating (coal, gas, oil) as a heat source, using the principle of thermal radiation drying (baking) material, by circulating hot air and hot air blower to achieve material is heated evenly, effectively guarantee drying (baking) materials the quality, color and taste. By feeding component transfer belt, motor, transmission, circulating fan, body, electrical control boxes and other components, by regulating the speed, and set the temperature of the roast material, effectively ensure the best baking results and so on.

With electricity (microwave) heating (coal, gas, oil) as a heat source, using the principle of thermal radiation drying (baking) material, by circulating hot air and hot air blower to achieve material is heated evenly, effectively guarantee drying (baking) materials the quality, color and taste. By feeding component transfer belt, motor, transmission, circulating fan, body, electrical control boxes and other components, by regulating the speed, and set the temperature of the roast material, effectively ensure the best baking results and so on.

Belt dryer baking machine

-

The egg washing machine body is made of 304 stainless steel plate, the chain bearings are all made of 304 material, the brush roller is made of high-strength nylon wire, and the egg rubber wheel is made of POM material, which can wash fresh eggs, salted eggs, mud-marinated eggs, preserved eggs, etc.

Fully Automatic Production Line Eggs Pasteurized Eggs Line Egg Liquid Processing Production Line