All Industries

Fruit and Vegetable Processing Equipments

Food & Beverage Machinery

Frying Processing Equipments

Meat Processing Machine

Oil Pressers

Nuts Processing Machines

Farm Machine

Other Food Processing Equipments

-

In the food processing industry, large-scale production often faces three core challenges: flavor inconsistency caused by uneven spraying, quality fluctuations due to insufficient coating precision, and production bottlenecks from delayed cooling. Now, the golden trio of “Coating Machine + Cooling Fan + Spray Cabinet” breaks down process barriers with a “Three-in-One” collaborative design, integrating the scattered processes of “spraying-coating-cooling” into a seamlessly connected high-efficiency production line. From uniform coating of chocolate beans to rapid freshness locking of baked cookies, and precise seasoning of snacks, this combination not only achieves a 99.5% coating integrity rate and ultra-fast cooling in 3-5 minutes but also increases overall production efficiency by 40% and reduces material loss by 25%. Fully complying with FDA food contact standards and industrial production needs, it serves as a core solution for controlling quality, cutting costs, and boosting capacity—whether for mass processing in large food factories or premium production in specialty workshops.

Commercial Food Coating Equipment: Coating Machine, Cooling Fan & Spray Cabinet

-

Non-Fried And Fried instant noodle machine noodle production line

-

The Electric Heating Homogenizing Mixing Tank is a multi-functional industrial equipment integrating heating, stirring, and homogenizing, designed for mixing, emulsifying, and dissolving liquid or semi-liquid materials. It features a stainless steel (304/316) tank body, electric heating system (temperature range: 0-150℃), and a high-speed homogenizer (3000-12000rpm) that breaks particles and disperses ingredients evenly. Equipped with a variable-speed stirring motor and a homogenizing head (usually located at the bottom or side), it ensures thorough mixing—preventing sedimentation and achieving uniform texture. The tank is designed with a sealed structure to avoid contamination, while the heating jacket provides stable temperature control, suitable for heat-sensitive materials. Widely used in food, cosmetics, pharmaceuticals, and chemical industries, it meets FDA and GMP standards for hygiene and safety.

Electric Heating Homogenizing Mixing Tank | Stainless Steel, Food-Grade for Liquid Mixing

-

1.Raw milk selection The first step in making yogurt is to carefully select high-quality raw milk, It is the core in the production of making yogurt. And the quality of raw milk directly determines the taste and quality of yogurt. The milk source must come from healthy cows, and strict hygiene standards must be followed during the collection and transportation process to ensure the purity and freshness of the fresh milk, without odor, impurities, and microbial contamination. High-quality milk should contain a high level of milk solids, including protein, fat, carbohydrates, vitamins, and minerals. Generally speaking, the milk solids content of raw milk is best between 11.5% and 13%. You can choose whole milk for better fermentation effect and taste. Low-fat or skim milk can also be used, but the taste may be slightly different. In addition to fresh milk, some high-quality milk powder is sometimes added to further adjust the nutritional content and taste of yogurt, making the yogurt thicker and richer. Store the raw milk in a refrigerated environment at around 4°C to prevent deterioration. 2.Filter, removal of impurities Raw milk may contain some impurities that are difficult to detect with the naked eye, such as dust and...

1.Raw milk selection The first step in making yogurt is to carefully select high-quality raw milk, It is the core in the production of making yogurt. And the quality of raw milk directly determines the taste and quality of yogurt. The milk source must come from healthy cows, and strict hygiene standards must be followed during the collection and transportation process to ensure the purity and freshness of the fresh milk, without odor, impurities, and microbial contamination. High-quality milk should contain a high level of milk solids, including protein, fat, carbohydrates, vitamins, and minerals. Generally speaking, the milk solids content of raw milk is best between 11.5% and 13%. You can choose whole milk for better fermentation effect and taste. Low-fat or skim milk can also be used, but the taste may be slightly different. In addition to fresh milk, some high-quality milk powder is sometimes added to further adjust the nutritional content and taste of yogurt, making the yogurt thicker and richer. Store the raw milk in a refrigerated environment at around 4°C to prevent deterioration. 2.Filter, removal of impurities Raw milk may contain some impurities that are difficult to detect with the naked eye, such as dust and...

Yogurt production instruction

-

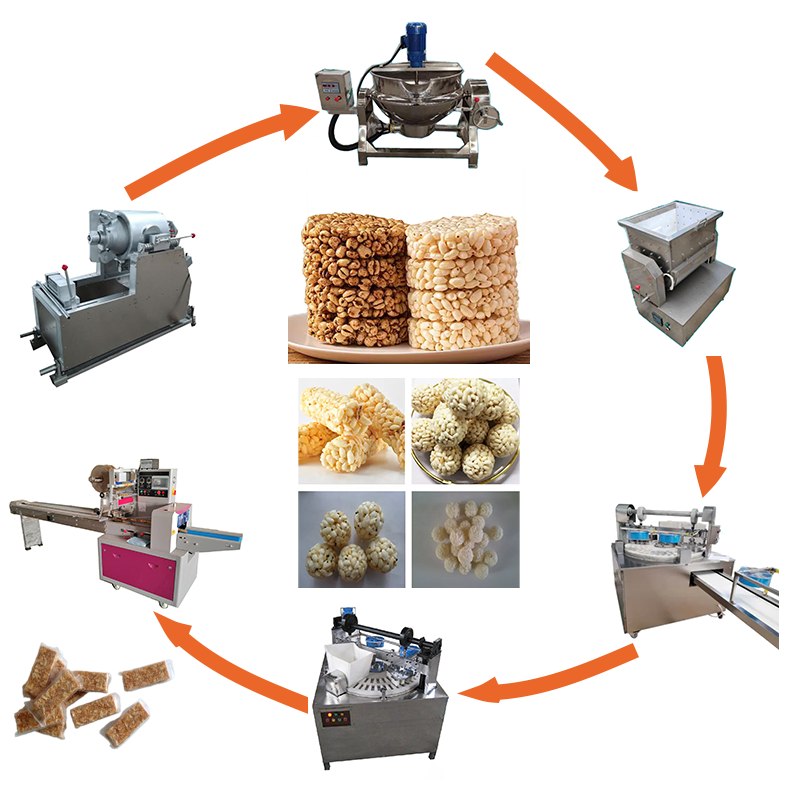

The rice cake making processing line need five machines :air puffing machine—-candy cooking machine—–mixing machine—-rice cake forming machine—packing machine. And then ,you can product the delicious rice cake.

The rice cake making processing line need five machines :air puffing machine—-candy cooking machine—–mixing machine—-rice cake forming machine—packing machine. And then ,you can product the delicious rice cake.

Multishaped Popped Rice Cake Cereal Bar Production Line

-

In the exciting world of food manufacturing, innovation and efficiency are key to staying ahead. One such innovation is the Puffed Rice Candy Cake Production Line, equipped with a state-of-the-art Popcorn Ball Forming Machine. This advanced production system is designed to cater to the growing demand for delicious, light, and crunchy puffed rice candy cakes, offering both manufacturers and consumers alike a delightful culinary experience.

In the exciting world of food manufacturing, innovation and efficiency are key to staying ahead. One such innovation is the Puffed Rice Candy Cake Production Line, equipped with a state-of-the-art Popcorn Ball Forming Machine. This advanced production system is designed to cater to the growing demand for delicious, light, and crunchy puffed rice candy cakes, offering both manufacturers and consumers alike a delightful culinary experience.

Puffed Rice Candy Cake Production Line Popcorn Ball Forming Machine