-

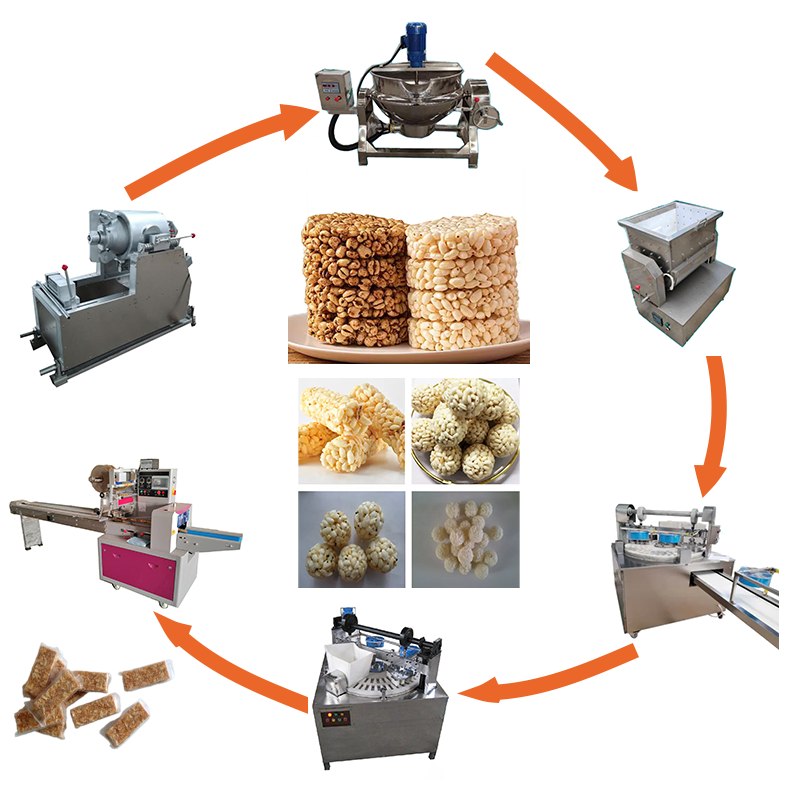

In the exciting world of food manufacturing, innovation and efficiency are key to staying ahead. One such innovation is the Puffed Rice Candy Cake Production Line, equipped with a state-of-the-art Popcorn Ball Forming Machine. This advanced production system is designed to cater to the growing demand for delicious, light, and crunchy puffed rice candy cakes, offering both manufacturers and consumers alike a delightful culinary experience.

In the exciting world of food manufacturing, innovation and efficiency are key to staying ahead. One such innovation is the Puffed Rice Candy Cake Production Line, equipped with a state-of-the-art Popcorn Ball Forming Machine. This advanced production system is designed to cater to the growing demand for delicious, light, and crunchy puffed rice candy cakes, offering both manufacturers and consumers alike a delightful culinary experience.

Puffed Rice Candy Cake Production Line Popcorn Ball Forming Machine

-

The integrated Roasting Peeling Color Sorting Packaging line is an “efficiency tool” for nut, grain, and seed food processing. Integrating automated roasting, precise peeling, 99% accuracy color sorting, and sterile packaging, it meets FDA/CE certification, boosts production efficiency by 40%, cuts labor costs by 30%, and fits large-scale production of almonds, cashews, quinoa, etc., providing food factories with a one-stop “raw material to finished product” processing solution.

Roasting Peeling Color Sorting Packaging Line: Automated Food Solution

-

High Efficiency Industrial Date Palm Olive Cherry Pitting Machine Dates Seed Removing Machine

-

The Essential Oil Extraction Tank is a precision-engineered device specializing in extracting aromatic essential oils from plants, herbs, and flowers via steam distillation—a time-tested method that preserves oil purity. Its core structure includes a stainless steel (304) distillation chamber, heating jacket, and condensation coil: hot steam penetrates plant materials to release oils, which then condense into a liquid mixture (oil + water) and separate naturally due to density differences. All contact parts meet food-grade standards, ensuring no contamination, while the easy-to-disassemble design simplifies cleaning and maintenance.

Batch Type Essential Oil Tank | Steam Distillation, Suitable for Small to Large-Scale Production

-

Fruit Sorting Machine The Best Quality Customized Stainless Steel Fruit Grading Machine

-

A stone mill is an ancient yet timeless milling device that utilizes a pair of circular millstones to process whole grains, nuts, and seeds into flour or pastes through a crushing and shearing action. Its fundamental principle has remained largely unchanged for millennia, prized for its ability to produce exceptionally high-quality, nutritious, and flavorful products. The core components of a stone mill are the millstones. Traditionally, these are carved from natural materials like granite or basalt, chosen for their hardness and natural, slightly porous texture. One stone is fixed (the bedstone), while the other rotates above it (the runner stone). The facing sides of both stones are engraved with a patterned series of grooves called furrows and flat areas called lands. These patterns are critical: they act as channels to draw raw grain into the center and distribute it evenly across the grinding surface, while the sharp edges of the lands perform the actual cutting and crushing. The process begins when whole grain is fed into the eye, a central hole in the runner stone. As the runner stone rotates—either by hand, water power, or in modern applications, an electric motor—the centrifugal force moves the grain outward between the stones....

Commercial Automatic Stone Grinding Mill CE Certified Traditional Stone Mill for Grain and Flour Production